Pioneer Process Equipments

The Company has been established on 4th March 2023.

We have established this Unit with a motive of producing High Class Quality products to be delivered to the valued Customer within agreed delivery time. The Company has an area ad – measuring 8000 Square feet with 5 Ton capacity EOT Crane, and have installed the Machinery and Equipments required for manufacturing pressure vessel, heat exc hanger, storage tank, condenser, reactor, mixing tank, pre-fabricated piping & skid in var ious material like stainless steel, carbon steel, duplex, super duplex, hastalloy,titanium & inconel.

Every member of the Company has adequate experience and knowledge of the product to be produced. Achieving Customer’s requirements to his satisfaction and winning his confidence by delivering Quality Product on time without any obligations is our Goal.

Every member of the Company has adequate experience and knowledge of the product to be produced. Achieving Customer’s requirements to his satisfaction and winning his confidence by delivering Quality Product on time without any obligations is our Goal.

Our reputation as a highly reliable supplier is built on our extensive knowledge and technical skills, always striving for continuous improvement. The demonstrated quality of our products is assured by adopting the highest competence into every step of the manufacturing process.

CAPABILITIES

Quality

Use of international codes like ASME, TEMA. We do consider any customised specification provided by the clients if any.

Manufacturing

We can fabricate to all major design codes, owning facilities. We fabricate equipment utilizing a wide variety of construction materials including Carbon, Low Alloy and Stainless Steels, Duplex, Super Duplex, Titanium, Steels, Hastalloy, Cu, Ni, and Cu-Ni alloys.

Welding techniques

FCAW, GTAW, SMAW. Includes all materials even most alloy ferritic & austenitic (i.e. duplex, super duplex, copper, hastalloy, titanium, cladded material & nickel alloys)

Welding Specialties

Tube to Tubesheet Joints: Manual, Bimetallic

: Cu-Ni to CS, cadded material (hastalloy + CS, Titanium + CS).

RECENT ACCOMPLISHMENTS

5 KL and 3KL Dosing System (Tank, Agitator, Piping & Skid) for M/s Fristam Pumps India Pvt Ltd.

Plinth for M/s Mahindra Defence System Limited

25KL Molecular Sieve Drum for M/s Aayan Multitrade LLP Unit II,have been successfully manufactured under the Client’s Inspection within stipulated time for their customer.

30KL Chemical Storage Tank for M/s Natural Biogenex Pvt Ltd, has been delivered on time.

Export (New Zealand)of Heating Tank, Cooling Tank, Heater & Storage Tank for M/S Maharashtra Engineers & Fabrication, successfully manufactured under the Client’s Inspection.

Export (Saudi Arabia) 20KL Hot Water & Cool Water Tank M/S ACME Process Systems Pvt Ltd, successfully manufactured under the Client’s Inspection.

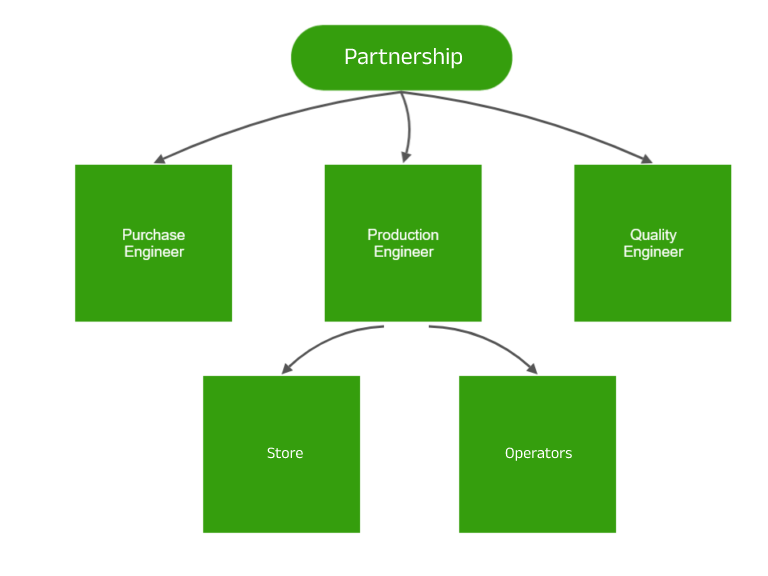

ORGANIZATION STRUCTURE

Our Products

- High Pressure Shell

- Heat Exchangers

- Pressure Vessels

- Gas Storage Vessels

- Water Treatment Skid

- Heating Steam Coil

Our Products

- Belows

- Storage Tank

- Pharma Process Equipments

- Reactor Vessel

- Mixing Tank

- Base Frame

Contact Us

- Unit I : Gat No 79 Jyotiba Nagar, Talawade, Pune - 411062

-

+91 9890737866

+91 9595541020 - info@pioneer-equipments.com